Table of Contents

Switchyards and substations are an integral part of the electrical generation, transmission, and distribution systems. And they are everywhere; there are for example 55,000 substations in the United States alone. Substations are typically surrounded by security fences, and it is standard to see coarse gravel installed on the ground inside and even outside these confines.

There are many misconceived beliefs as to the reasons why gravel is laid in substations.

There are in fact two main reasons why gravel is laid inside substations: 1. Improved safety during earth faults and lightning strikes; and 2. Improved fire suppression during oil fires.

1. Gravel improves safety during electrical faults

Laying a high resistivity surface material like gravel in switchyards increases the allowable step and touch voltages, thereby reducing the risk of shocks to humans in the vicinity of the grounding system, during an earth fault.

“Touch voltage is the potential difference between the ground potential rise (GPR) of a ground grid or system and the surface potential at the point where a person could be standing while at the same time having a hand in contact with a grounded structure” (IEEE 80:2013 [1]).

“Step voltage is the difference in surface potential that could be experienced by a person bridging a distance of 1 m with the feet without contacting any grounded object” (IEEE 80:2013 [1]).

Potential differences can cause an electric current to flow through the body of the person under ground fault conditions. The current will be large enough to cause ventricular fibrillation resulting in fatality of humans when the touch and/or step voltages generated during these faults exceed the permissible limits. These permissible limits can be calculated based on the impedance of the human body, the duration of the fault, and foot impedance.

When a surface material such as gravel which has a higher soil resistivity is laid over the native soil, the surface layer acts as an insulating layer. Therefore, the contact resistance between the ground surface and feet of a human increases. This increases the effective resistance of the human body, thereby lowering the fault currents which could flow through the human body whilst in contact with the ground, and in effect, raising the permissible touch and step voltage limits a human could withstand during a fault condition.

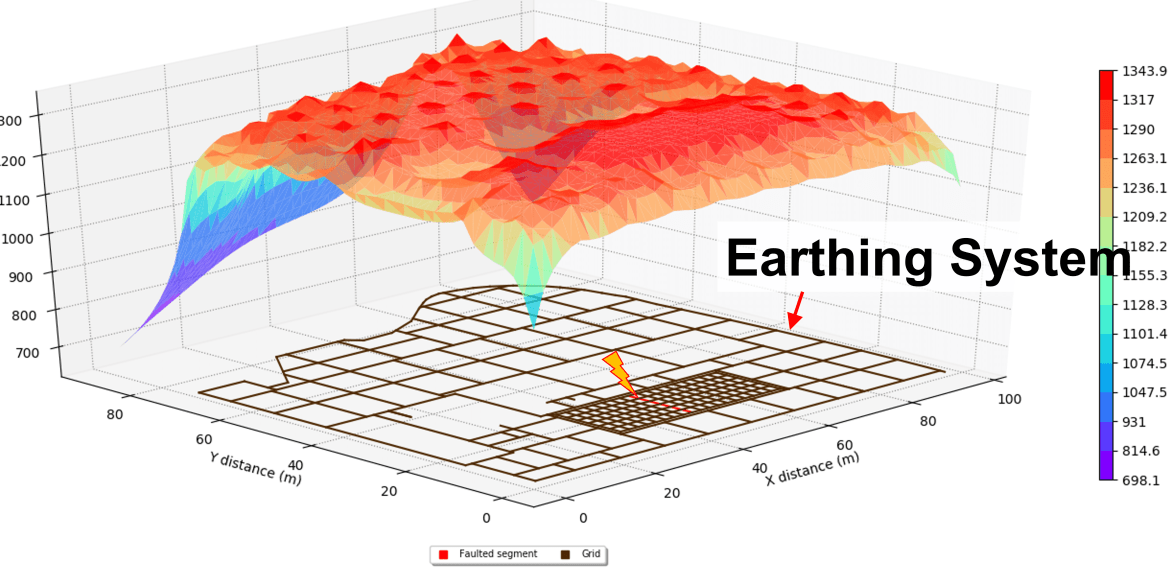

The advantage of adding a high resistivity surface layer such as crushed rock to a substation can be demonstrated using a computer simulation.

The software being used for the modelling is ELEK SafeGrid Earthing Software.

In this example, an earth fault was simulated to flow into a 30 x 30 metre uniform meshed grid which is buried at 0.5 metre depth in multi-layered soil. Actual touch voltages were calculated to reach 518.8 V during the fault.

To determine whether the substation would be safe for people a tolerable touch voltage limit was calculated using standard IEC 60479 [2]. For a fault clearing time of 0.5 seconds and without a high resistivity surface layer on the ground the permissible touch voltage limit was only 143.83 V – therefore the substation would be unsafe for people during a fault since the actual touch voltages at many locations around the substation (particularly around the outer perimeter) exceeded this limit. However, if a 100 mm thick layer of crushed rock surface layer was considered then the permissible touch voltage limit increased to 817.6 V which is greater than the actual maximum touch voltage.

Figure 1: Software calculation of maximum permissible touch voltage with and without high resistivity gravel surface layer

Figure 2: 2D distribution of touch voltage without (left) and with (right) additional gravel surface layer

The effective resistivity of the surface layer further depends on the type and size of stone used, local conditions such as moisture and dust levels. Dry gravel has higher soil resistivity than wet gravel (typically wet resistivity of 3000 Ω.m is assumed for modelling). The presence of dust or underlying soil within the gaps of surface gravel can compromise its effectiveness, by decreasing the resistivity of the surface layer. This is one of the main reasons why it is important to properly maintain the gravel laid in and around substations.

2. Gravel suppresses fire and flames

Gravel is used both in open areas inside substations and around oil-insulated equipment for fire protection and to prevent the spread of fire. Outdoor switchgear equipment such as circuit breakers and transformers use mineral oil as their insulating/cooling medium. Failure of such equipment can cause fires and spread of fires through explosions and oil spillage. IEEE 979 [3] notes that using stones of diameter 18 mm as ground surface material can quench mineral oil combustion by lowering the combustion temperature and controlling the availability of combustion air.

AS 2067 [4] also recommends the use of gravel in common sumps and containment tanks to prevent the spread of fire from one transformer to another. However, the volume of oil contained would depend on the void space of the surface gravel layer and so containment pits with gravel will be larger in size.

Although gravel is not the primary protection for grounding faults and fires (ground fault protection and firefighting equipment are the primary protective measures), it acts as a secondary level of protection in switchyards and substations, minimizing the effect of such failures when they occur.

![Figure 3: Rocks used for oil fire suppression in bund surrounding transformer [4]

Figure 3: Rocks used for oil fire suppression in bund surrounding transformer [4]](https://eq8y3wpwe77.exactdn.com/wp-content/uploads/2023/04/Rocks-used-for-transformer-oil-fire-suppression.png?strip=all&lossy=1&ssl=1)

References:

[1] IEEE Std 80-2013 – IEEE Guide for Safety in AC Substation Grounding

[2] IEC 60479-1:2018 – Effects of current on human beings and livestock – Part 1: General aspects

[3] IEEE 979-2012 – IEEE Guide for Substation Fire Protection

[3] AS 2067:2016 – Substations and high voltage installations exceeding 1 kV a.c.