Current Rating of Buried Cables: Soil Drying and Moisture Migration Explained

The conductor temperature of a cable is the primary constraint in calculating the ampacity. For buried power cables, the surrounding soil serves as the primary medium for heat dissipation, with soil thermal resistivity being the most critical thermal property influencing this process. When cable generate heat this can cause soil drying and moisture migration that reduces the current rating and potentially leading to overheating.

Soil drying occurs when heat from buried cables creates a temperature gradient, causing moisture to migrate away from the cable surface. This migration results in the formation of a dry zone around the cables. Dry soil has significantly higher thermal resistivity compared to moist soil, which restricts the ability of the soil to dissipate heat effectively.

Case studies demonstrate that neglecting soil drying effects can lead to undersized cable installations. For example, considering soil drying, direct-buried cables show 20% lower ampacity than calculations that ignore this phenomenon. Conversely, engineered backfill allows cables to maintain higher ratings even with 100 % (continuous) loading.

Thermal Resistivity of Soil

The thermal resistivity of soil is a critical parameter in determining how effectively heat generated by buried cables can dissipate into the surrounding environment. Moisture content, soil type, compaction, and temperature, influence the thermal resistivity of soil.

Refer to the article on the typical thermal resistivity of backfill soils and concrete.

Impact of Moisture Content on Thermal Resistivity

Moisture content plays a dominant role in soil thermal resistivity. Moist soils typically have low thermal resistivity (0.5–1.5 K.m/W), while dry soils can exhibit values two to three times higher (2.0–3.0 K.m/W). This sharp increase in resistivity as soils dry underscores why moisture migration caused by cable heating is so critical to consider during the design and operation.

Temperature Dependence of Thermal Resistivity

Soil thermal resistivity also varies with temperature. For example:

At 20°C, moist soil may have low resistivity due to water’s high thermal conductivity.

If moisture migration is limited by thermally stable materials surrounding the cables such as engineered backfills, resistivity may decrease slightly due to enhanced heat transfer within dry particles at elevated temperatures.

However, when moisture migration occurs freely, high temperatures exacerbate drying and increase resistivity over time.

Soil Drying Around Cables

Heat from cables may cause significant moisture migration away from cables. The main cause is a temperature gradient. A dry soil zone may develop around the cables. There is a sharp transition from low thermal resistivity to high as drying occurs.

Moisture migration is a dynamic process that’s extremely complicated.

Negative Impacts of Soil Drying

External thermal resistance significantly influences cable ampacity, accounting for over 70% of the temperature increase in buried cables. Soil thermal resistivity also significantly affects external thermal resistance.

The outer cable surface is typically 50-70 % of the conductor temperature.

If a dried-out zone forms around the cables, an abrupt rise in cable temperature may cause thermal runaway leading to damage.

Famous cases of thermal runaway caused by soil drying are:

- Auckland power supply failure 1998.

- London, UK in 1962 (two 132 kV cables).

Soil Drying Prevention Measures

The following methods may be used in order to prevent soil drying out:

- Use of controlled backfilling material.

- Increase the installation depth to reach more thermally stable soils.

- Use a spaced flat formation instead of a trefoil formation to distribute the heat over a larger area.

- Install Distributed Temperature Sensors (DTS) to detect hot spots before any irreversible damage to the cable insulation occurs.

Two-zone (IEC) Soil Drying Model

The IEC 60287 standard models soil drying using a simplified two-zone approach. Initially, moist soil is assumed to have uniform thermal resistivity. When a buried cable operates, heat dissipation raises its surface temperature. If this temperature exceeds a critical threshold (typically 50 °C), moisture migration begins, creating a concentric dry zone around the cable.

Note that the critical soil temperature can be calculated using a simple German VDE 0276-1000 Standard equation.

This dry zone exhibits a uniform thermal resistivity 2–3 times higher than the original moist soil, forming distinct boundaries. The interface between the dry and wet zones is modelled as isothermal, maintaining a constant temperature equal to the soil’s critical drying temperature.

Read this article, which explains the limitations of the two-zone model for soil dry-out ampacity calculations.

Multi-zone Model - ELEK® Method

The ELEK® method extends beyond the IEC limitations, considering soil drying out, cyclic load, backfill/duct enclosure, and multiple circuits with unbalanced loads simultaneously.

With this method, the installation is divided into multiple zones with uniform thermal resistivity. The backfill is assumed to be thermally stable and free of moisture migration. ELEK® Method further considers actual cable positions and power losses.

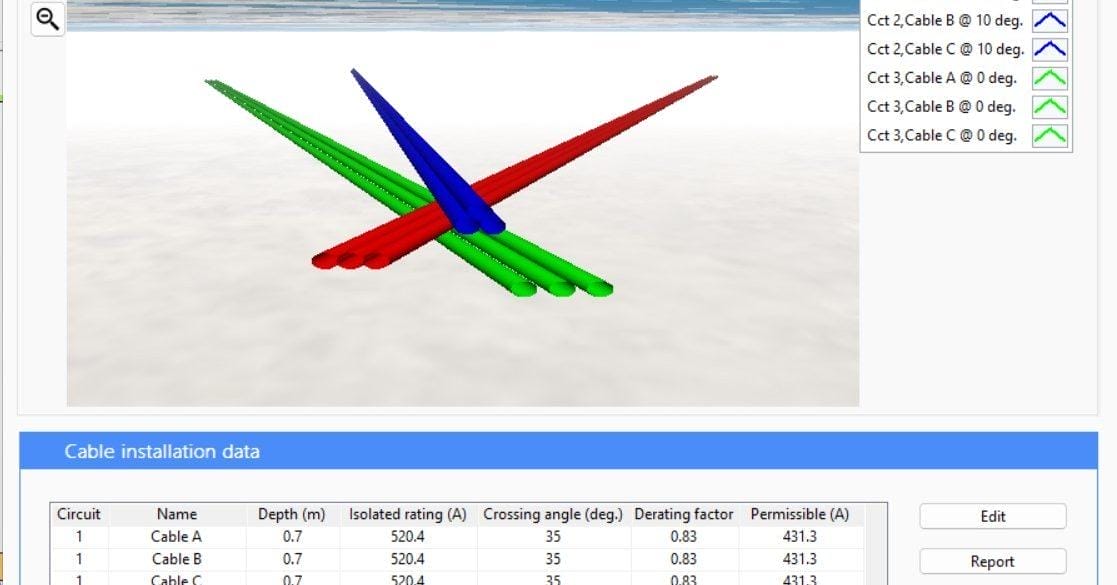

Example Software Calculations - Multiple Buried Circuits with Soil Dryout

The high-level steps to an FEM cable rating calculation are as follows:

1. Multiple buried circuits with soil dry out

This calculation example demonstrates how soil dry-out significantly affects the current-carrying capacity for a group of four 33 kV cable circuits, both directly buried or in a backfill.

Native soil thermal resistivity is assumed to be 1 K.m/W, while the backfill thermal resistivity is 0.6 K.m/W. Dry native soil thermal resistivity is assumed to be 2.5 K.m/W at a critical soil temperature of 50 °C (based on a two-zone model). The load factor varied from 1 (continuous maximum rated current) to 0.75.

The main observations include:

- Ampacity reduces significantly if soil drying-out is taken into consideration.

- Ampacity increases linearly with non-unity (decreasing) load factor.

2. Soil dry-out prevention modelling

Soil dry-out prevention assumes dry-out will begin when the native soil is exposed to a temperature of 50 °C. One way of managing this risk is to ensure the 50 °C isotherm is fully within the thermally stable backfill during the cable system’s operation.

A special algorithm in ELEK Cable HV Software automatically calculates the current ratings to prevent the 50 °C isotherm from extending beyond the backfill boundary.