If you use accurate software to calculate your cable sizes and perform voltage drop calculations you will save an average 75 % of your time and $3,366 in cable costs compared with performing hand calculations.

Cable selection process

The following main factors involving calculations influence the selection of correct cable sizes:

1) Current-carrying capacity. 2) Derating factor selection. 3) Voltage drop. 4) Short-circuit performance. 5) Fault loop impedance.

The calculations procedures are outlined by the Standards however they may take significant time to perform by hand and finding the optimal cable sizes, usually requiring the use of software, will often save significant project costs.

How to save 75 % of your time

Using software for cable sizing saves a significant amount of your time compared with performing hand calculations. Software calculations are more reliable and more accurate.

Several factors which affect cable size need to be calculated and often re-calculated to arrive at a safe and optimal solution. In the first example below the time it took to perform manual calculations was 38 minutes compared with only 7 minutes using ELEK software.

In addition to this the software also produced detailed and a well-presented finished report.

How to save $3,366 in cable costs

Software calculations are very accurate often resulting in optimal solutions which saves you money. The algorithms in software use more accurate methods of calculation than is possible by hand such as accurate voltage drop, short-circuit and fault loop impedance calculations.

In the example below software was used to calculate voltage drop which considered cable operating temperature and load power factor resulted in a smaller cable size from 50 mm2 down to 35 mm2 for the 225 m run resulting in a cable costs saving of $3,366.

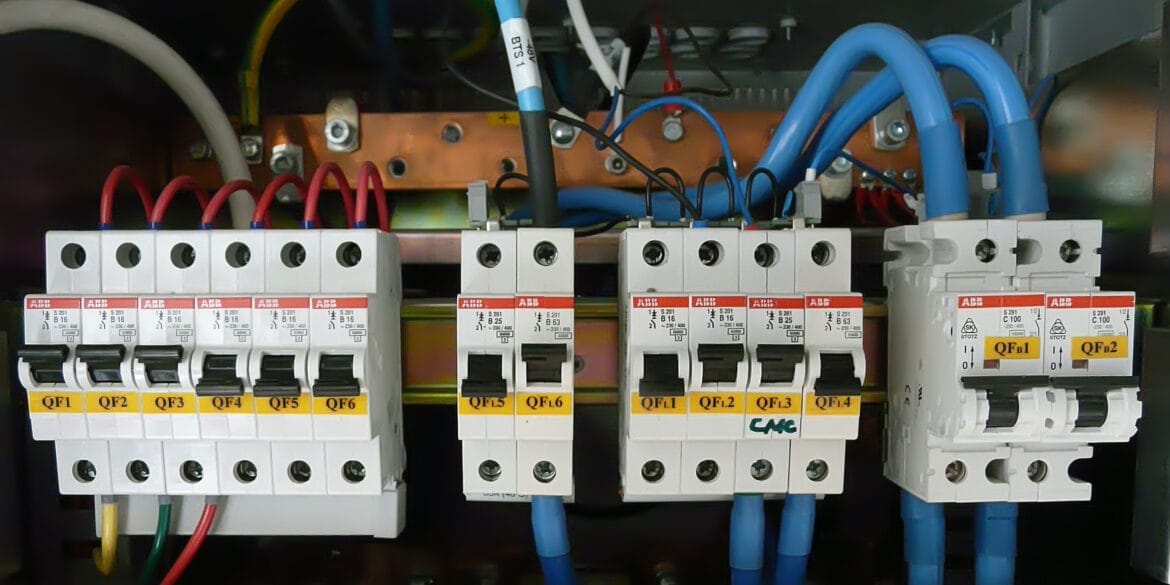

Example 1 - Six 4 core cables to 22 kV motors

PROBLEM EXPLAINED

This example calculation is based on Example 4 in Appendix A of AS/NZS 3008.1.1.

Six four-core V-75 insulated and sheathed copper cables are arranged touching in a single horizontal row on a perforated cable tray for the supply of six identical 22 kW motors which have a full-load current of 45 A per phase and are installed at distances of 40 m, 55 m, 90 m, 135 m, 180 m and 225 m from the origin of the cable tray. Determine the minimum conductor size if a voltage drop of 2.4 % (10 V) is permitted for each cable.

SOLUTION – hand calculations (38 minutes)

The same approach used in the worked example by the Standard is as follows. The cable sizes required to satisfy the voltage drop restriction were assessed using the simple voltage drop equation and voltage drop (mV/A.m) values given in Tables 40 and 51 given for various cable types and configurations and limited to maximum operating temperatures which is conservative.

In comparison the same calculations took only 7 minutes using software!