Why are cables derated?

The current rating of a cable is affected significantly by the installation conditions and the external environment. For example, cables may be installed in air or buried underground and will have a different current rating. In general, the same cables when installed in air have a higher current rating than when they are buried. The ambient temperature of the air or soil also affects current rating.

There are so many possible installation conditions and different environmental conditions. Therefore, the Standards for low voltage cable sizing such as AS/NZS 3008.1, BS 7671, and IEC 60364-5-52 provide current ratings tables for fixed (standard) installation conditions.

These standards also provide derating factor tables to be applied to the cable current ratings when the actual installation conditions for your project differ from the standard conditions. These derating factors most often reduce, but sometimes increase, the effective current carrying capacity for your cables ensuring that the temperature limits for those cables are not exceeded.

You can determine derating factors directly from the tables in the standards or using Cable Pro Web Software has a simple-to-use Wizard for derating factors.

The main factors that derate cables

Ambient temperature – The current rating of a cable depends on the difference between the ambient temperature and the temperature limit for the cable. Therefore the same cables installed in colder environments will have a higher current rating than for the cables in hot environments.

Different countries have different standard ambient temperatures to be used for cable current ratings and these can be obtained from IEC 60287-3-1 for specific countries.

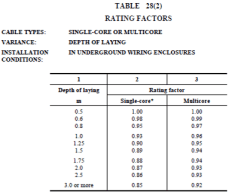

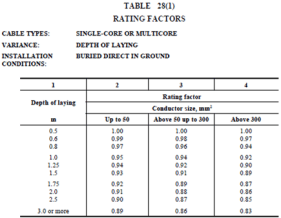

Depth of burial – The depth a cable is buried affects it’s ability to dissipate heat and therefore is a strong determinant of the current rating. Cables that are buried at deeper depths get hotter and therefore need to be derated. A typical depth of burial for low voltage cables is 0.5 metres (or 0.7 metres is assumed for BS 7671).

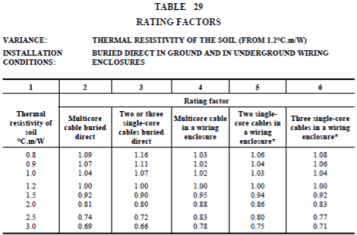

Thermal resistivity of soil – For buried cables one of the main factors that affects the current rating is the soil thermal resistivity which varies depending on soil composition, moisture content, seasonal weather patterns, and is affected by the loading of cables causing dry-out of soils.

A typical soil thermal resistivity is 1.2 K.m/W but varies between 0.8 K.m/W for clay or peat soils, and up to about 2.5 K.m/W for well-drained (low moisture content) soils with heavily loaded cables.

Varying loads (load factor) – Generally it is assumed by the low voltage cable sizing standards that the cables are continuously loaded, however when that is not the case then the current rating of the cables can actually be uprated.

Harmonic currents – The presence of third harmonic currents will cause additional joule losses in the cables which causes additional heating resulting in a derating of the current rating.

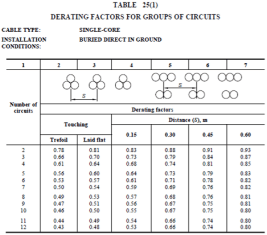

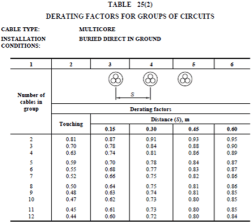

Groups of parallel circuits (mutual heating) in air (on trays or ladders) or buried – Cable circuits installed in proximity to other cable circuits will mutually heat one another and this mutual heating needs to be accounted for with derating factors for grouping of circuits.

When can derating factors be avoided?

Note that since the current rating tables for all low voltage cable sizing standards mentioned above are derived based on the IEC 60287 standard methods then in general the ratings and derating factors from all standards can be interchanged – but be careful about the assumed standard conditions. For example the standard ambient temperatures in Australia are higher than in the United Kingdom.

How to use derating factors

1. Obtain the current rating based on the standard conditions.

2. Determine the factors from the derating factor tables for your installation conditions.

3. Multiply all of the derating factors together and then multiply this value by the standard (tabulated) current rating of the cable to obtain the derated cable current rating.

Low voltage cable derating factors -

Australian and New Zealand conditions

Derating factor tables

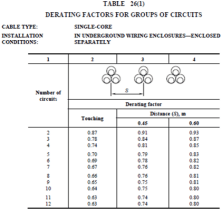

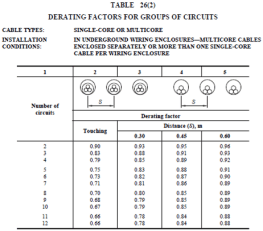

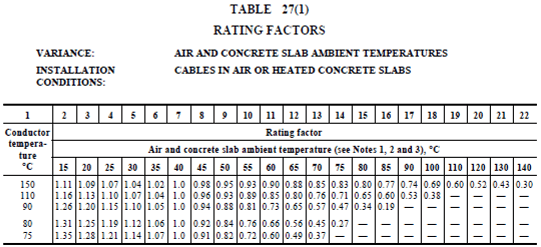

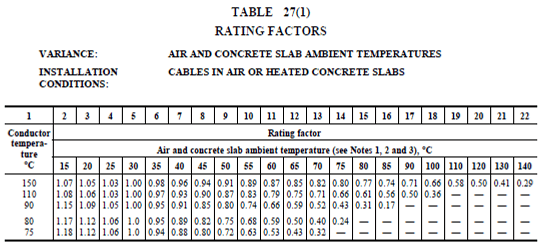

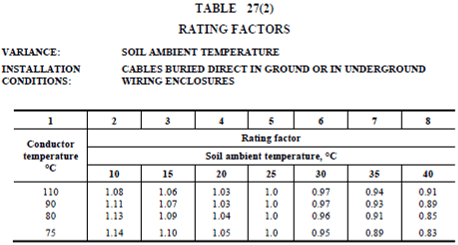

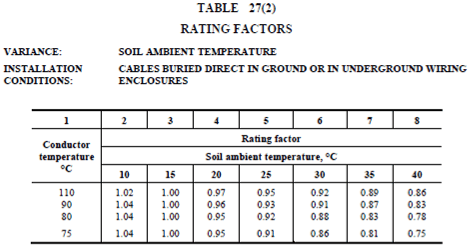

The derating factor Tables below are from both AS/NZS 3008.1.1 (Australian conditions) and AS/NZS 3008.1.2 (New Zealand conditions). The Tables from both standards are the same except for TABLE 27(1) and 27(2) which differ.

Disclaimer: No responsibility is assumed for the accuracy of the Tables below. Further, there are additional notes to these tables that have not been included.

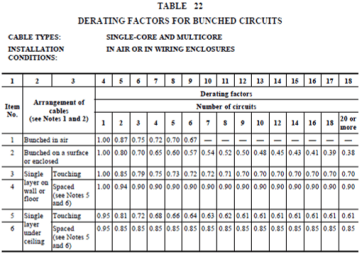

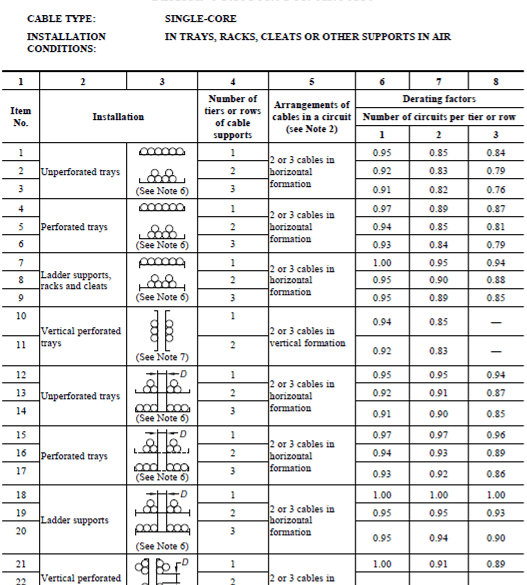

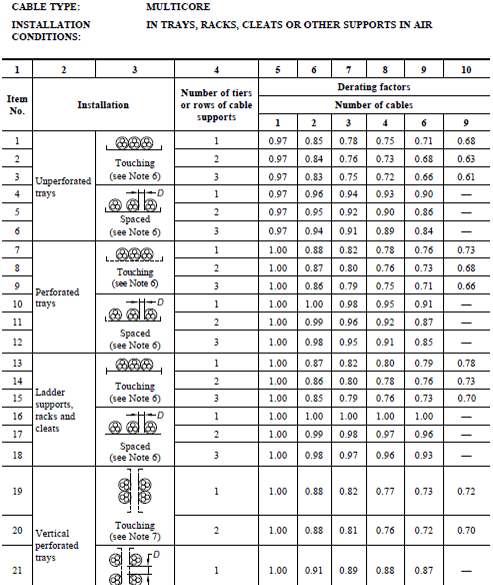

In Air - Derating factor tables for groups of bunched circuits, in trays or on cable ladders

Ambient air temperature and concrete slab temperature derating factor tables

Buried - Soil ambient temperature, buried in enclosures and thermal resistivity of soils derating factor tables

Buried - Direct buried cable derating factor tables for groups of single core and multicore cables, and depth of burial

Buried - In enclosures for groups of single core and multicore cables, and depth of burial derating factor tables