Table of Contents

Cable Modelling and Ampacity Accuracy

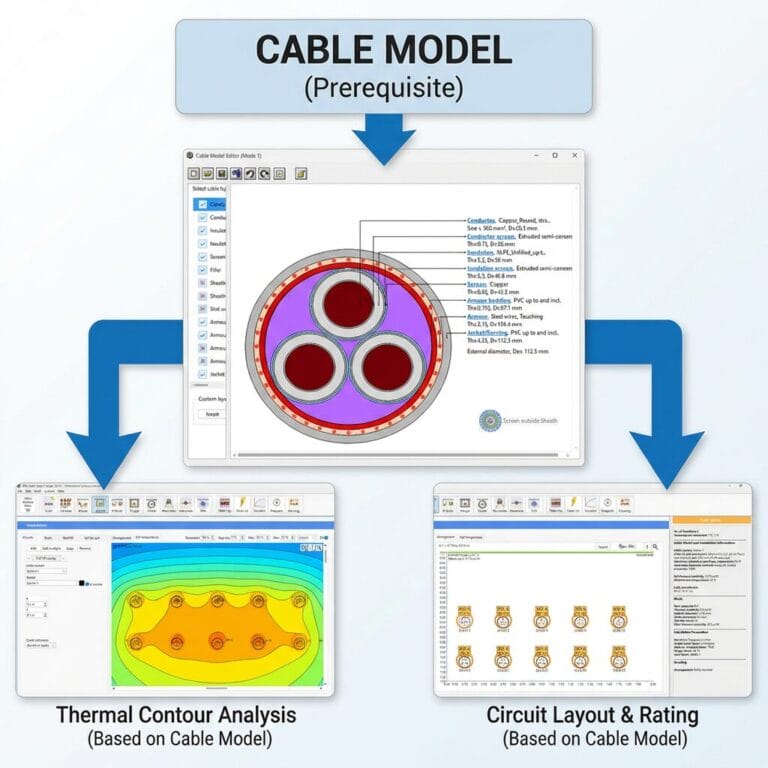

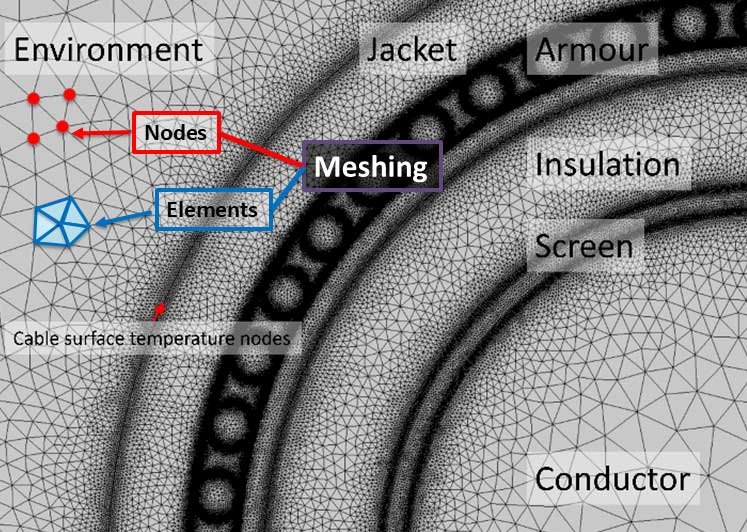

Cable modelling is the most critical and time-consuming step and is the prerequisite to performing cable ampacity studies. For IEC 60287 current rating calculations, a cable must be represented as a radial thermal network of concentric insulating and metallic layers, which requires defining each layer, including its geometry and thermal and electrical material properties. Even small errors in cable geometry or material definitions in the model can result in conductor temperature errors of tens of degrees. Proper cable modelling requires a detailed understanding of cable construction and materials, of which a cable manufacturer’s datasheet is typically relied upon.

Presentation Slides

Download the full PDF slide deck of this article for your reference.

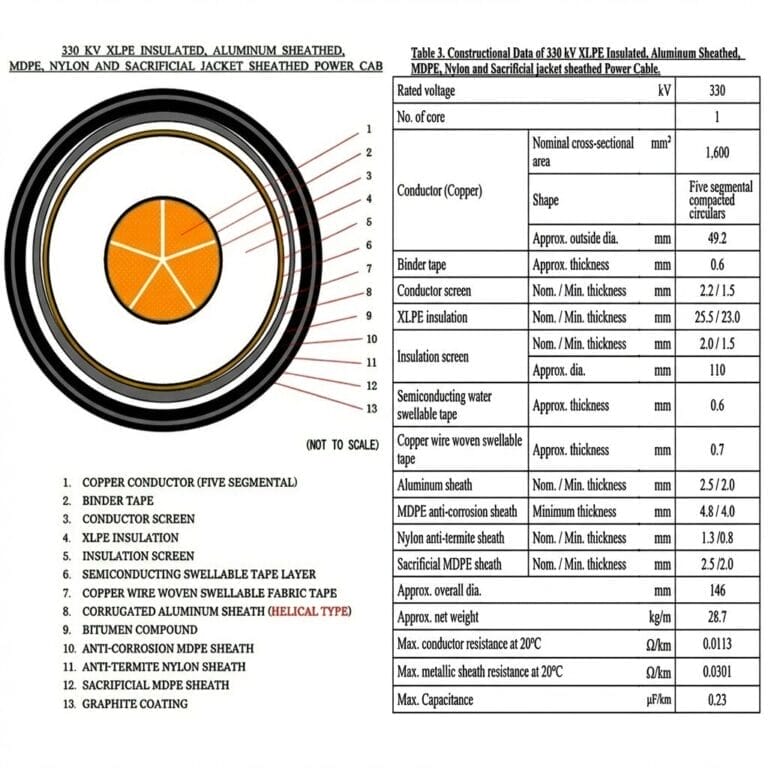

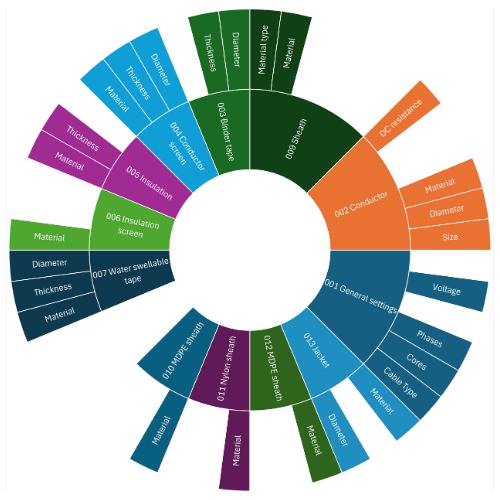

Datasheets for high-voltage power cables (see example below) typically define cables manufactured with between 5 to 12 layers, but they often do not provide the complete, layer-by-layer geometric and material definitions required for IEC 60287 calculations. Intermediate layers are often omitted, thicknesses are given without matching diameters, and materials are described using manufacturer-specific terminology that does not map directly to IEC material categories. Therefore, significant engineering expertise and experience are required to construct an accurate cable model. Furthermore, since it’s a manual process, it’s often slow and prone to human errors.

Manual Cable Modelling Workflow for Ampacity Studies

Experienced cable engineers follow a process when modelling cables for ampacity calculations:

- Obtain the Cable Datasheet (PDF) from the Manufacturer

- Specify the Cores and the Rated Voltage Level

- Extract the Layers and Layer Order

- Determine the Layer Dimensions

- Define the Layer Materials

- Engineering Validation of the Model

This process is repeated for every cable type and project and typically requires 30 – 90 minutes per cable when performed manually.

AI-Assisted Cable Modelling for IEC 60287

Generative AI can assist cable modelling by extracting cable layers, dimensions, and material descriptions from manufacturer datasheets for IEC 60287 ampacity studies.

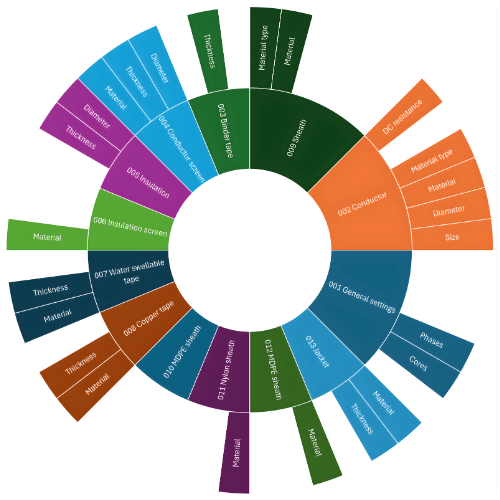

When general-purpose LLMs such as ChatGPT™ and Claude™ are used, only explicitly stated values in the datasheet are extracted. Missing layers, incomplete dimensions, material mapping to IEC 60287 definitions, and model consistency must be resolved manually before a calculation-ready cable model can be produced.

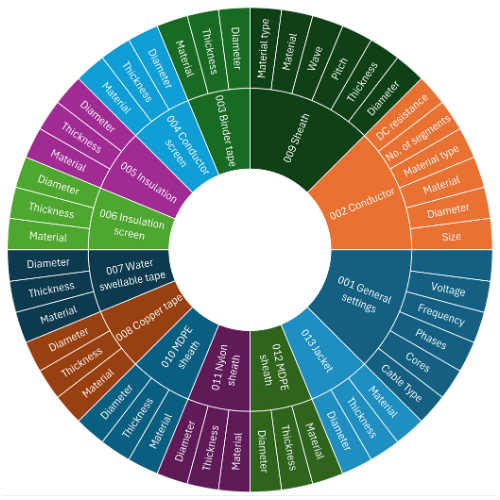

A custom-trained AI model, such as ELEK AI™, applies cable modelling rules during interpretation. In addition to extracting datasheet data, it identifies all functional layers, derives missing geometric parameters, maps materials to IEC 60287 categories, and assembles a complete radial cable model.

The ELEK AI workflow is as follows:

- The manufacturer’s cable datasheet (PDF) is ingested

- A cable model with AI reasoning is returned

- The engineer verifies the model

Note that the engineer remains responsible for reviewing and approving the final cable model.

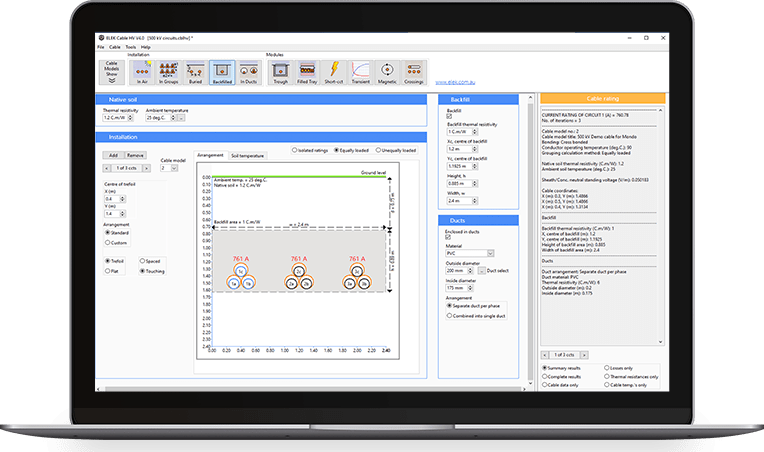

Case Study: 330 kV Cable Modelling for IEC 60287

A case study was carried out using a 330 kV single-core cable with a 1600 mm² copper conductor. The manufacturer’s datasheet contains incomplete geometric information typical of HV cable datasheets, including missing layer diameters, thickness ranges without absolute dimensions, and construction details shown primarily in drawings.

A reference cable model was constructed manually by an experienced cable engineer and treated as the correct representation of the cable for IEC 60287 ampacity calculations.

Cable models were generated independently from the same datasheet using ChatGPT™, Claude™, and ELEK AI™. The generated models were compared against the reference model based on layer completeness, dimensional consistency, and material definition.

The ELEK AI™ model matched the reference cable model with an overall accuracy of 100% and was generated in 3 minutes and 16 seconds.

The ChatGPT™ model achieved an overall accuracy of 52.36% and required 12 minutes and 29 seconds, with several missing layers and incomplete dimensional definitions.

The Claude™ model achieved an overall accuracy of 50.25% and was generated in 1 minute 34 seconds, but, like the other models, failed to resolve missing dimensions and layer definitions.

Only the ELEK AI™ model was suitable for direct use in IEC 60287 ampacity calculations without manual modification, subject to engineering verification.

Key Modelling Observations

- Missing and derived geometry: Multiple layer diameters were not specified in the datasheet. General-purpose LLMs could not resolve these gaps, while ELEK AI™ identified or calculated all layer diameters using cable modelling rules.

- Rule-based parameter inference: The operating frequency was not stated in the datasheet and could not be identified by general-purpose LLMs. ELEK AI™ inferred the frequency based on established modelling rules.

- Precedence and error propagation: The insulation screen was specified with a 110 mm diameter and 2.0 / 1.5 mm thickness. In accordance with standards, the explicit diameter takes precedence, resulting in a calculated thickness of 2.1 mm. An incorrect diameter at this stage would propagate errors through all subsequent layers.

- Construction interpretation: A copper woven layer was misclassified as a screen by general-purpose LLMs, and corrugated sheath geometry (wave height and pitch) was not identified. ELEK AI™ correctly interpreted the functional layer role and incorporated corrugation geometry in accordance with construction rules.

Key Findings and Practical Implications

Ampacity and Cable Modelling FAQs

Do you require a cable datasheet for an ampacity calculation?

To perform accurate cable ampacity studies, it’s necessary to create a model of the cable cross-section that includes the thicknesses and material properties of the cable’s materials. To obtain this information, you need to request the datasheet from the cable manufacturer.

What happens if cable layer dimensions are missing from the datasheet?

All layers within a cable must be properly defined, including thicknesses and diameters, to perform cable ampacity studies. Often, cable datasheets lack dimensions, and sometimes these dimensions can be inferred or back-calculated from the other layer dimensions provided.

How do errors in cable modelling affect ampacity calculations?

Small errors in a cable model can significantly impact the ampacity of power cables. Some errors can cause fatal issues in the calculations, rendering them unable to be performed.

How many cable layers are typically required for an IEC 60287 model?

The minimum number of cable layers required to model ampacity is 2, including the conductor and insulation. Real power cables have several layers, typically 3-5 layers for low-voltage cables and 5-12 layers for high-voltage cables.

Which cable layers contribute to thermal resistance in IEC 60287?

The insulating layers inside a power cable include the main insulation (typically XLPE) or other internal dielectric materials, bedding layers, fillers, and the cable jacket.

Which cable layers contribute to electrical losses in ampacity calculations?

All metallic layers inside an AC power cable contribute to the electrical losses. The extent to which they contribute depends significantly on the bonding arrangement of the metallic cable layers.

References

[1] IEC 60287-1-1, Electric cables – Calculation of the current rating – Part 1-1: Current rating equations (100 % load factor) and calculation of losses – General, International Electrotechnical Commission.

[2] IEC 60840, Power cables with extruded insulation and their accessories for rated voltages above 30 kV (Um = 36 kV) up to 150 kV (Um = 170 kV) – Test methods and requirements, International Electrotechnical Commission.

[3] IEC 62067, Power cables with extruded insulation and their accessories for rated voltages above 150 kV (Um = 170 kV) up to 500 kV (Um = 550 kV) – Test methods and requirements, International Electrotechnical Commission.