Table of Contents

Purpose of cable sheath bonding

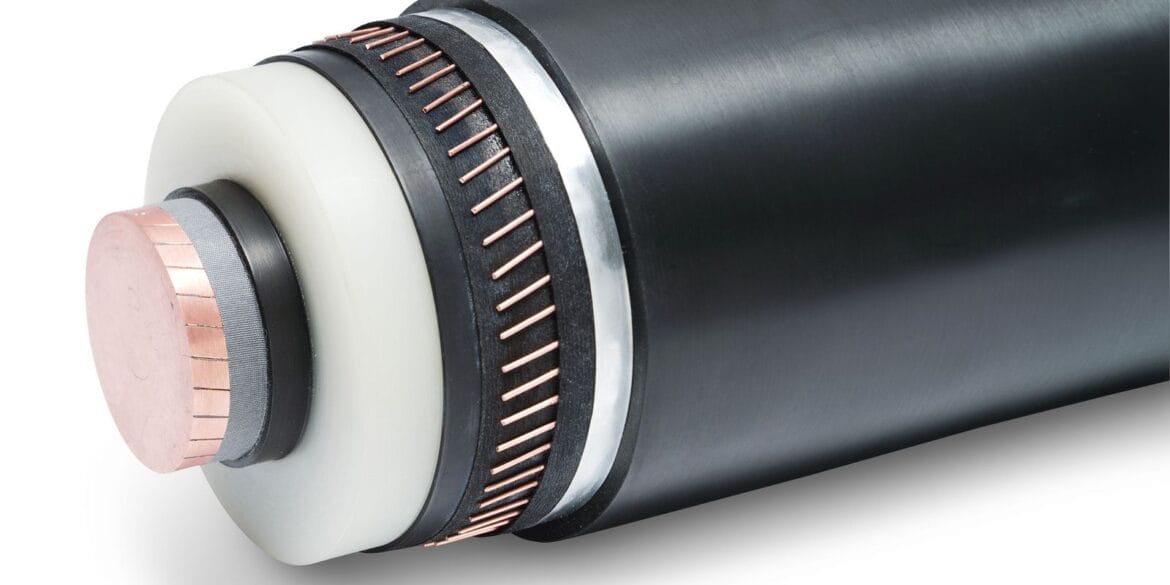

High-voltage power cables are provided with an outer concentric conductor in the form of a metal screen and/or a metal sheath which surrounds the main conductor and insulation layer. Metal screens and metal sheaths are collectively referred to as the sheath. The sheath also includes any metallic armour layer(s) in the cable. The purposes of a cable metal sheath include to provide fault current return path, return path for the induced capacitive charge currents, earth (zero touch voltage or thereabouts) potential for human safety, and moisture barrier for cable insulation.

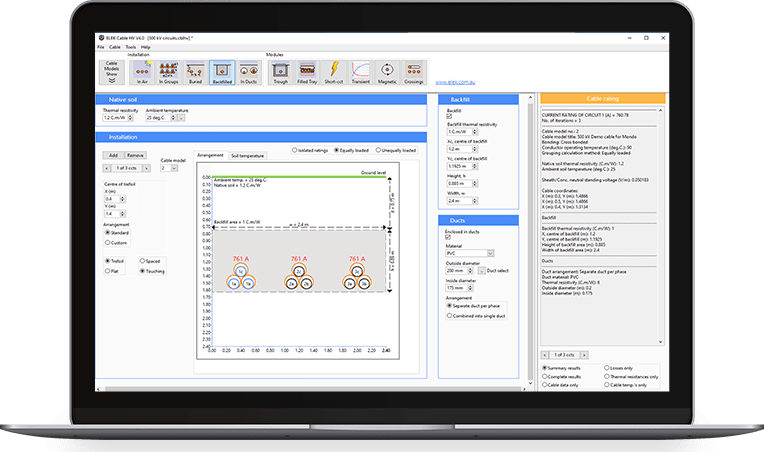

For high-voltage cable circuits carrying more than about 500 A, sheath bonding arrangements are implemented to reduce (often significantly) sheath current losses. Whilst the bonding arrangements come with an additional cost for equipment and maintenance, they will often result in considerably smaller cable sizes to be used for supplying the same load currents. The metal sheath bonding arrangement selected for high-voltage cable systems has the second highest impact on cable current ratings, second only to the external thermal resistance (the installed environment) to the cables. High voltage cable current ratings are calculated using the IEC 60287 Standard series.

A sheath bonding system is used for protecting the insulation of various cable system components during normal operation as well as from transient overvoltage from lightning, switching and fault surges. Moreover, the sheath bonding arrangement is also important from a safety point of view.

In this report we explain the following types: solid bonding, single-point bonding, cross-bonding, and impedance bonding.

Sectionized cross-bonding is the most common special bonding arrangement for HV and EHV transmission lines except if the line length is short then single-point bonding is mostly used.

Refer to separate articles for earth continuity conductor (ECC) design, sheath voltage limiter (SVL) selection, and bonding lead selection.

Losses in the cable sheath

The magnetic field that is generated from the current flow in the main conductors of cables creates a “transformer” effect that induces a current in the sheath. Due to these induced currents in the sheath two types of losses can occur: circulating current losses and eddy current losses. The presence of current losses in the sheath causes additional heating inside the cable resulting in reduced current-carrying capacity of the cables conductor.

The eddy currents circulate radially and longitudinally of the cable sheaths; and are generated on similar principles of skin and proximity effects. The eddy currents are generally of smaller magnitude compared with circulating current and they are generated in the cable sheath irrespective of the bonding system of single core cables.

If circulating currents are present in the sheath (depending on the sheath bonding arrangement) their current magnitude is generally much greater than that of the eddy currents.

Circulating currents occur in the sheath for solid bonding of single core cables and multicore cables where an individual sheath surrounds each conductor core. For sheaths that are single-point or cross-bonded there are no circulating currents, however eddy current losses still occur.

Sheath bonding designs

Solid bonding

Method

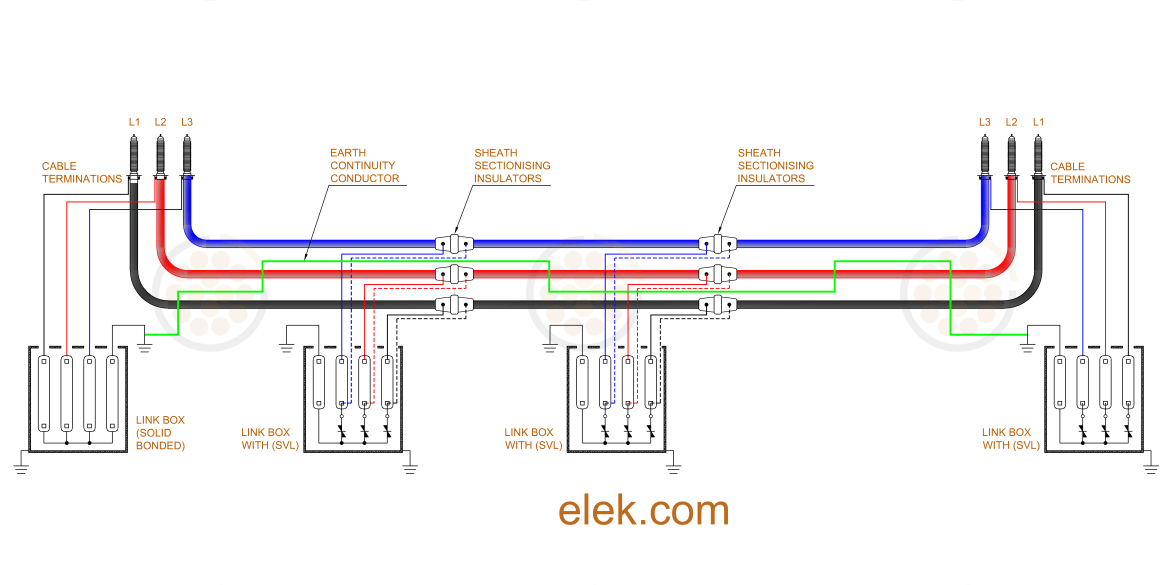

Figure 1. Solid bonded cable system

Figure 2. Solid bonding system with intermediate earthing points

Application

Advantages

- Simple and low-cost solution.

- The magnetic field external to the cable is low due to the opposing sheath current direction concerning the conductor currents.

- Minimal maintenance is required.

- The sheath's voltage is considered at the earth’s potential at every point.

Disadvantages

- The current flowing in the cable conductors will induce circulating currents into the sheaths which can be up to 80 % of the conductor current.

- The heat generated through joule losses by the circulating current flow will cause additional heating which will de-rate the cable system and result in larger cable sizes for solid bonding arrangements.

Design Considerations

- Use two independent parallel earth bonding leads at each bonding point (end or mid) to reduce the likelihood of disconnection.

- Bonding leads at the earth points must be capable of withstanding the fault currents.

- Depending on the length and other parameters, intermediate earthing points may be included.

- The magnitude of the circulating current is independent of the circuit length.

Single-point bonding

Method

Figure 3. Single-point bonded cable system

Figure 4. Sectionalised single-point bonded cable system

Application

Advantages

- Single point bonding provides improved cable current ratings since the induced circulating current losses in the sheath are eliminated.

- Only one length of the cable is required which makes single-point bonding an economical solution.

- The current does not flow longitudinally along the sheaths. This is because there is no continuous closed-loop electrical path for the sheath. Consequently, the sheath circulating current losses are eliminated. (Note that the sheath eddy losses will still be present).

Disadvantages

- This method causes voltage to rise along the length of the cable and these voltages are proportional to the conductor current and cable length. For single-core cables this voltage increases with the individual phase spacing.

- To reduce this voltage an ECC is installed that runs parallel to the cables and this significantly adds to the cost of the cable system

- Care must be taken to insulate the sheath at the free end to avoid danger from the induced voltages.

Design Considerations

In a single point bonded cable system a voltage is induced on the sheath of the cable during operation, progressively increasing with the distance away from the earthed point. This induced voltage reaches a maximum at the farthest point away from the earthed end. Therefore, the maximum cable section length is governed by the permissible sheath standing voltage allowed at the isolated end.

The induced voltage on the sheath must be calculated to not exceed an acceptable touch voltage limit for safety reasons. Most countries have a national standard that governs the maximum standing voltages allowed at power frequencies, as this is an important issue, particularly for maintenance workers, and these voltage limits are typically in the range of 35-400 V depending on the country and the regulations applied.

At points farthest away from the earthed end, the sheath must be effectively insulated from earth for the life of the cable system. If the anticipated surge voltage level is greater than 75% of the sheath insulator’s basic insulation level (BIL), a sheath voltage limiter (SVL) should always be utilised. The SVL is commonly connected between the open-ended sheath and the earth point to protect the cable sheath from overvoltage during transients caused by switching, lighting or faults.

An ECC is installed in parallel with the cables of a single-point bonded system except where both ends of the cable share a common earthing system. The relative location of the ECC with respect to the phase conductors should be carefully considered and the ECC should be transposed in the middle of the cable system.

Cross-bonding

Method

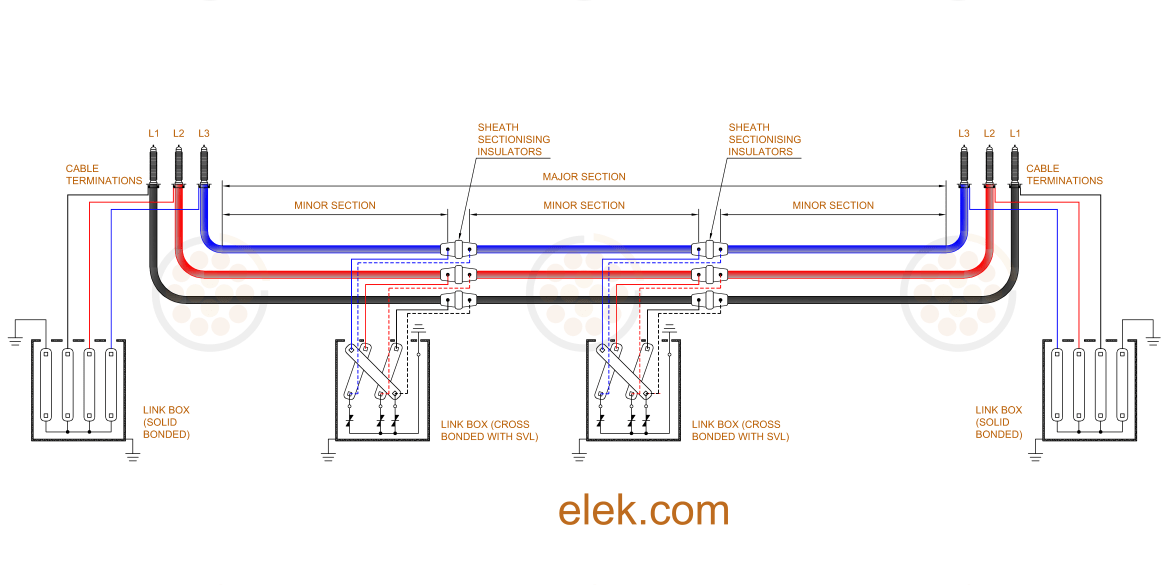

Figure 5. Cross-bonded cables without transposition

Figure 6. Cross-bonded cables with transposition

Types

Continuous Type of Cross-bonding

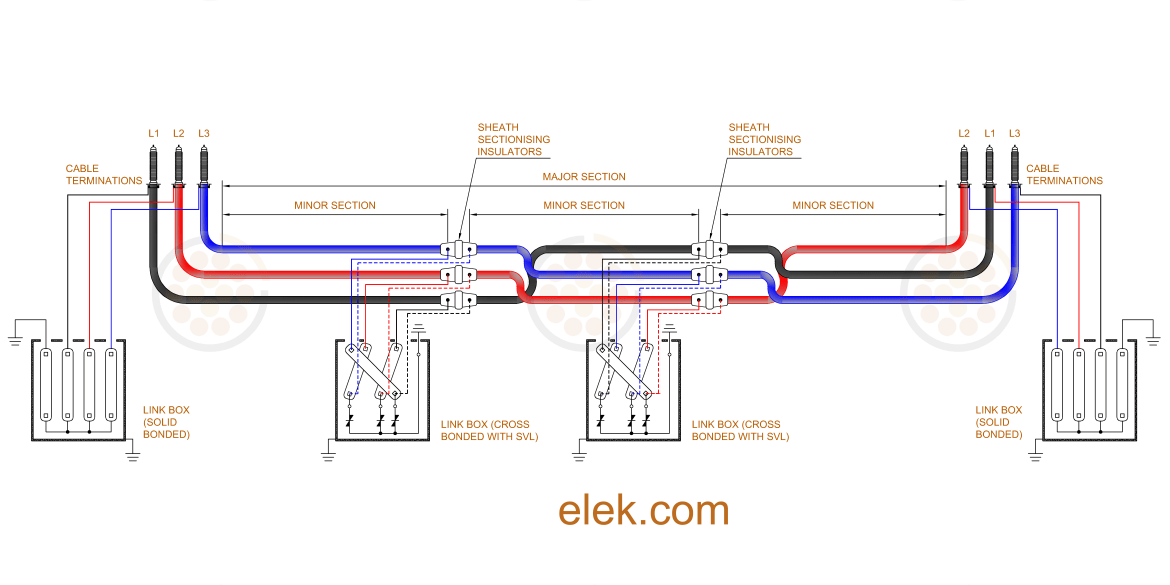

Sectionalized Cross-bonding

Direct Cross-bonding

Cross-bonding of Short Lines

Cross-bonding in Tunnel Installations

Although in this arrangement the cross-bonding leads do not carry surge current, these leads must be sized to carry system short circuit currents. Compared to regular cross-bonding where the SVLs are connected in a star arrangement, the SVL in tunnel installation is connected in a delta arrangement. Due to higher induced voltages during normal and transient conditions, a higher-rated voltage for the SVL is required in this type of installation.

Applications

Advantages

- Compared to single-point bonding, a cross-bonded configuration has the advantage of not being length limited.

- Circulating currents are significantly reduced, resulting in lower sheath losses and higher cable current ratings.

- Besides inhibiting sheath currents during the normal balanced load operation, the sheaths do form a continuous path from end to end of the cable circuit and are grounded at both ends. Therefore, during ground faults, sheath currents can flow across the length, thus eliminating the need for a separate ECC.

- In addition to the economy via eliminating the ECC, the cable sheaths function more effectively as screening conductors during earth faults than a parallel ECC. Hence, the voltages induced in parallel cables, communication lines, pipelines, fences, etc., are reduced during earth faults in a cross-bonded system versus a similar single-point bonded system.

Disadvantages

- Costly and complicated.

- Cross-bonding of sheaths significantly reduces the circulating current in sheaths. However, there is a challenge to ensure that all sections are of the same length.

Design Considerations

The length of each section and cable spacings are limited by the induced voltage levels and the voltage differences between the sheaths and the earthing points.

For cross-bonded cable circuits the highest sheath-to-earth voltages are caused by two-and three-phase faults. If the cross-bonded cable circuit is inserted in the middle of an overhead line, single-phase faults produce the highest sheath-to-earth voltages that increase with earth impedances.

Impedance bonding

Method

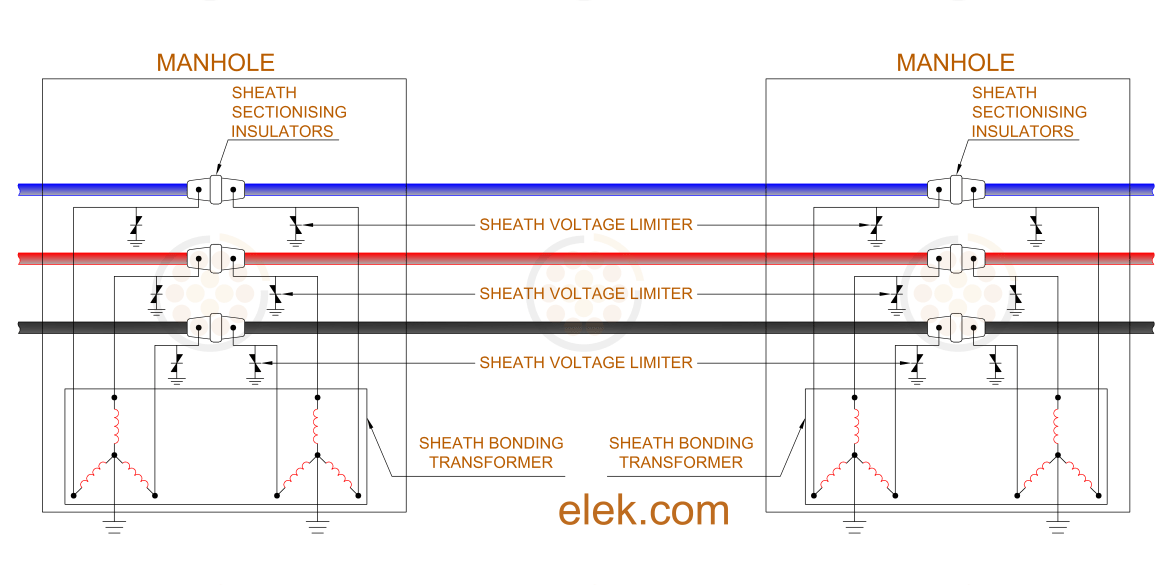

In the transformer sheath bonding, both ends of each cable sheath are electrically connected to a three-phase sheath bonding transformer as shown in Figure 7.

Figure 7. Impedance bonding via sheath bonding transformers

Application

Advantages

- The bonding transformer scheme is effective in limiting induced sheath currents regardless of whether the distances between cable vaults are equal or unequal.

Disadvantages

- Additional vault space is required.

- The impedance devices are relatively expensive since they must be designed to withstand fault currents

- During normal operation, third harmonics can be induced into the sheath, and these can cause interference on nearby telecommunication lines.

- Stray direct currents entering through the grounding can cause saturation of the iron cores and upset the operation of the reactors or transformers.

Design Considerations

Conclusions

Sheath bonding is one of the most important design aspects, requiring careful consideration, for high voltage power cable transmission. Cable sheath bonding serves a multitude of purposes and has a significant impact on the overall cost of the system and on the current rating of the cables.