Downloads:

Widely accepted XLPE cable temperature limits

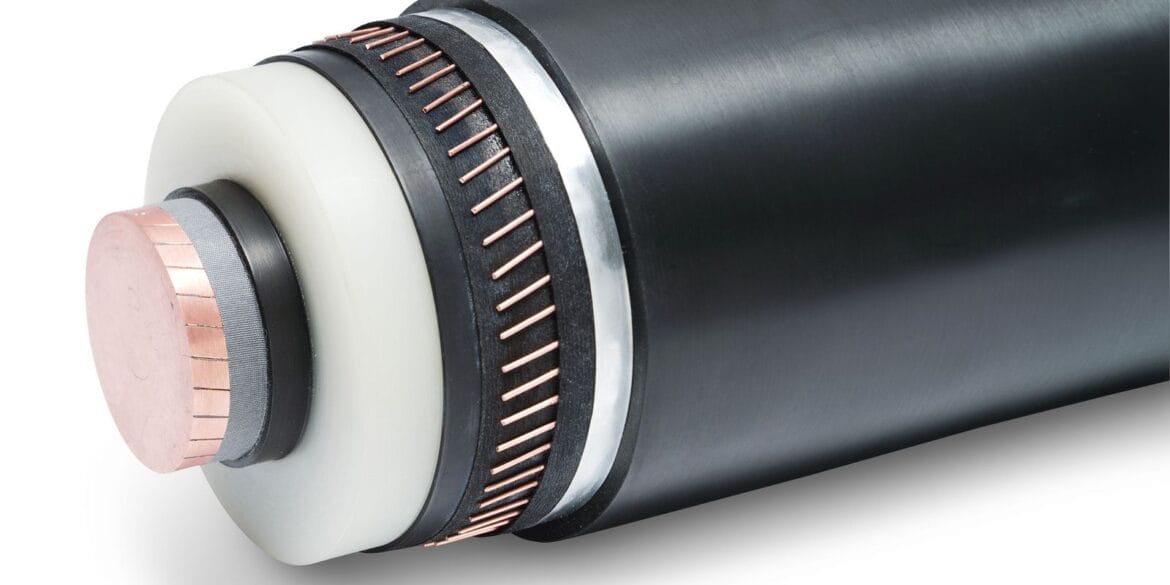

The current loading of a power cable system leads to the heating of that cable system. There is a limitation on the conductor temperature to avoid overheating of the adjacent insulation layers.

The widely accepted maximum operating temperature of XLPE insulated power cables under “normal use” conditions is 90 ˚C.

During emergencies, the temperature of a buried cable may be permitted to exceed the normal use temperature. The duration considered for such emergencies ranges from 10 minutes up to 15 days [5]. In many countries, XLPE-insulated cables are allowed to operate up to 100-105 ˚C for short durations [6].

! Emergency temperature limits of power cables apply to buried cables ONLY. Cables that are installed in the air must never exceed their normal use operating temperature.

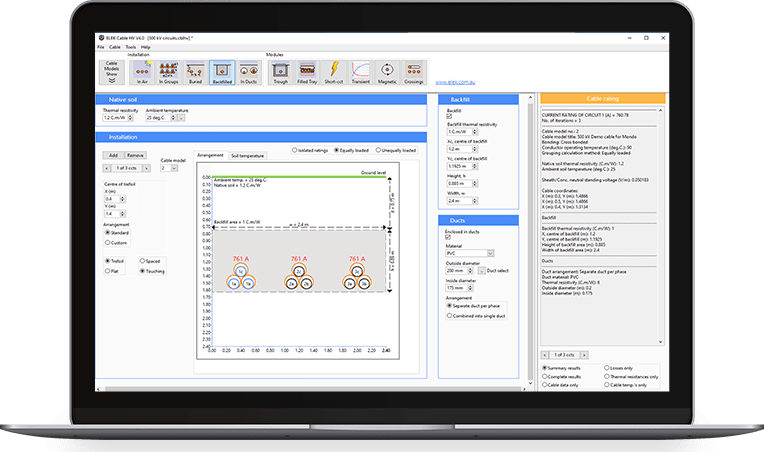

It is critical to establish the temperature limits before performing ampacity calculations. The entire cable system should be considered including different installation conditions, thermal bottlenecks along the route (of 5 metres length or greater [5]), and temperature limits of accessories, terminations, and joints. However, there is a strong argument that for many applications higher temperatures could be attributed to sections of the cable route without accessories, meaning that only the cable itself must be qualified for establishing the maximum temperature limit [6].

For buried cables limits imposed on the jacket temperature or the interface between backfill and native soil designed to avoid drying out of the surrounding soil will impose severe reductions on the maximum operating temperature. Similarly, significant cable operating temperature reductions may apply for cables installed inside tunnels or air-filled troughs to limit the air temperature rise.

IEC and US Standards

The IEC standards specify only a single value for the maximum conductor temperature, for both continuous and short-term operation. The American (US) standards specify a maximum normal operating temperature and a higher emergency temperature for a limited duration of 72 hours, which is explained as the average time to recover from a forced outage affecting equipment other than cables. Note that short-circuit temperature limits are not covered by this report.

| Continuous limit | Short-term limit | |

|---|---|---|

|

IEC Standards IEC 60840 IEC 62067 |

Maximum conductor temperature = 90 ˚C | Maximum conductor temperature = 90 ˚C |

|

US Standards AEIC CS9 ICEA S-108-720 |

Maximum operating temperature = 90 ˚C | Emergency operating temperature = 105 ˚C, for not more than 72 hours on average per year and not exceeding 216 hours in any 12-month period. |

XLPE material temperature limit explained

XLPE as a material has been around for a long time (XLPE was invented in the year 1963) and effectively replaced paper insulation in high voltage power cables. The advantages of XLPE insulation include its low electrical loss, high electrical breakdown strength, low cost and high thermal stability. Different grades of XLPE insulation will have different operating temperature limits. Increasing the temperature of XLPE insulation beyond it’s operating limits has irreversible degrading effects on performance and reduces cable lifespan.

The temperature limits of XLPE come from the base product upon which it is derived which is polyethylene (PE). PE is thermally stable up to about 85 ˚C. The melting temperature of most commercial PE grades is between 105 ˚C and 110 ˚C. High-density PE has a melting temperature of 130 ˚C.

The melting temperatures for conventional XLPE and heat-resistant XLPE are 103 ˚C and 123 ˚C, respectively. Thus, it makes sense to limit the continuous operating temperature of XLPE to 90 ˚C.

HVDC cables that are insulated using XLPE have an additional temperature limit constraint which is the temperature drop across the insulation.

The well-known temperature limit of XLPE has been around for a long time, and with consideration for the technological advances of cables, with advanced numerical software modelling and live temperature monitoring being commonplace, and with pressure for network owners to operate at higher temperatures, it’s relevance today is being questioned [6].

Temperature limits on cable accessories

The cable must be treated as a system and so the evaluation of the temperature limit of the cable insulation together with the cable accessories will ensure good service life of the cable. The thermal rating of the relays, current transformers, and the relay settings should be arranged to be above the emergency rating of the cable systems.

The thermal expansion of XLPE insulation is significant above 80 ˚C. Mechanical accessories on XLPE cables operating near their temperature limits must be capable of withstanding the outward radial stress caused by the expanding XLPE, but more critically they must deal with the thermal contraction as XLPE cools which can lead to electrically weak interface and partial discharge inception.

Mechanical cable accessories such as terminations or joints are rarely the limiting factor for the operating temperature of cable systems. A major reason is they are often installed in locations where the cooling is via the air and they have increased separation as a consequence of the working space required to be installed.

Conclusions

As per the standards, the maximum operating temperature of XLPE cables is 90 ˚C. Under emergency conditons the short-time temperature limit is 105 ˚C for up to 72 hours.

The XLPE insulation limitation is often the dictating factor for the temperature limit of the cable system. Rarely is it dictated by the cable accessories.

Good reasons exist for the long-standing and standardised continuous temperature limit for XLPE insulation of 90 ˚C. However, there is a recent push towards increasing these limits.

Heat cycle voltage testing (a rigorous form of type testing suggested by AEIC CS9 [3]) provides confidence around specifying emergency temperature limits for XLPE cable systems. In these tests the cable, accessories and monitoring system are tested as a whole system simulating the actual installation conditions on site, and the cable temperature and partial discharges are measured after each stage of the test [7].

References

[1] IEC 60840:2020, Power cables with extruded insulation and their accessories for rated voltages above 30 kV (Um= 36 kV) up to 150 kV (Um = 170 kV) – Test methods and requirements.

[2] IEC 62067:2022, Power cables with extruded insulation and their accessories for rated voltages above 150 kV (Um = 170 kV) up to 500 kV (Um = 550 kV) – Test methods and requirements.

[3] AEIC CS9, Specification for Extruded Insulation Power Cables and Their Accessories Rated Above 46kV through 345 KVac – 3rd Edition.

[4] ICEA S-108-720-2018, Standard for Extruded Insulation Power Cables Rated Above 46 Through 500 KV AC.

[5] CIGRE TB 640, A guide for rating calculations of insulated cables.

[6] Pilgrim, J., et. al., Thermal Limit of XLPE insulation: Is 90 still the magic number?, CIGRE 2024 Paris Session.

[7] Tang, K., et. al., 330kV XLPE Cable Specific Testing Protocol Requirements, CIGRE 2014 Paris Session.