Table of Contents

Introduction

Horizontal Directional Drilling of Power Cables

Video Overview: This video explains the key ampacity considerations for power cables installed using HDD, building on the information presented in this article.

Presentation Slides

Download the full PDF slide deck of this article for your reference.

Ampacity of Cables Installed using HDD

The ampacity of cables installed using HDD depends on a multitude of factors, including, but not limited to, cable construction, soil resistivity, burial depth, duct or pipe sizes and materials, cable configuration within ducts and pipes, duct filling materials, and moisture migration or dry-out. This article offers an in-depth examination of cable ampacity in HDD installations, combining theoretical insights, case studies, and practical engineering guidance.

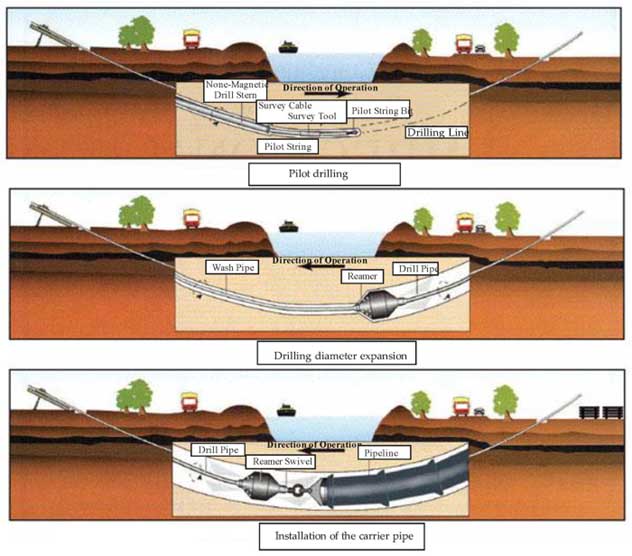

HDD Cable Installation Method

Design Tip: For the polyethylene (PE) pipes or ducts, the safe long-term deflection is 7.5% of the diameter (ASTM F1962-11). Many manufacturers suggest using a bend radius of about 40–50 times the pipe diameter during installation.

Traditional HDD Versus HDD for Cable Systems

- Depth Limitation: HDD installations for cable systems are constrained in depth because greater burial depths increase thermal resistance, which in turn reduces cable ampacity.

- Length Limitation: HDD installations for cable systems are also constrained in length due to the maximum allowable pulling tension that can be applied to power cables during installation.

HDD Cable Configurations

Table 1: Pros and cons of different HDD cable configurations shown in Figure 2.

| HDD Cables Configuration | Pros | Cons |

|---|---|---|

| Direct-buried cables Figure 2: (d) |

|

|

| Cables-in-ducts in a casing pipe Figure 2: (a) |

|

|

| Cables in separate-ducts Figure 2: (c) |

|

|

| Cables in a casing pipe Figure 2: (b) |

|

|

Case Study: 132 kV Cable Installed via HDD (10 m Depth)

In a real-world HDD installation, the cables are installed at various depths along the drill path. Cable ampacity is significantly affected by burial depth. In general, the deeper the cables are installed, the lower their ampacity. To understand how cable ampacity varies with burial depth, refer to this article. The deepest section of the HDD bore path is usually the hottest point; however, this is not always the case. Other problem sections can be at the ends of bentonite-filled ducts or pipes that may have air gaps. The soil around the HDD pipe or ducts may also dry out, causing a hotspot. This hotspot usually occurs at the deepest point, just above the water table level.

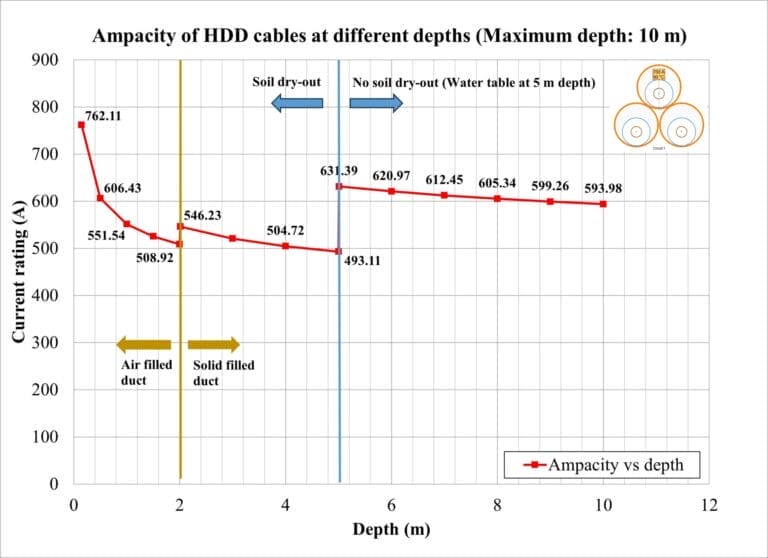

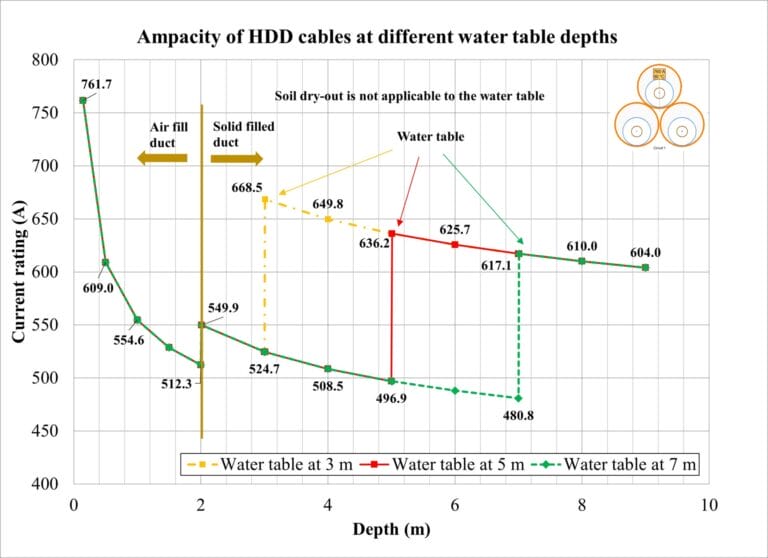

Figure 3 illustrates the ampacity of the HDD cable along its route, from the surface to a depth of 10 m, taking into account the variable characteristics of different sections. The depth above which the section of the duct is air-filled, and the depth at which soil becomes sufficiently moist to prevent dry-out (i.e., below the water table at 5 m) are marked on the figure.

The observations from the figure are given below.

- Ampacity decreases with depth, regardless of the duct material or the soil dry-out.

- Ampacity falls sharply for an air-filled section.

- The deepest point does not determine the HDD cable ampacity.

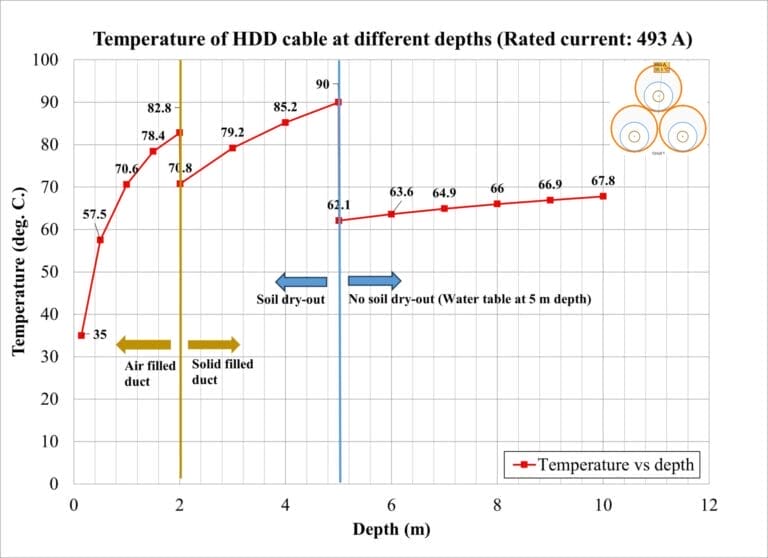

Figure 4 shows the cable temperature versus burial depth at the rated current of the HDD cable (493 A), illustrating the significant temperature differences across different sections. It can be seen from the figure that the potential hot zones are the deepest points of the air-filled section and just above the water table.

Factors Affecting HDD Cable Ampacity

Different Duct Configurations

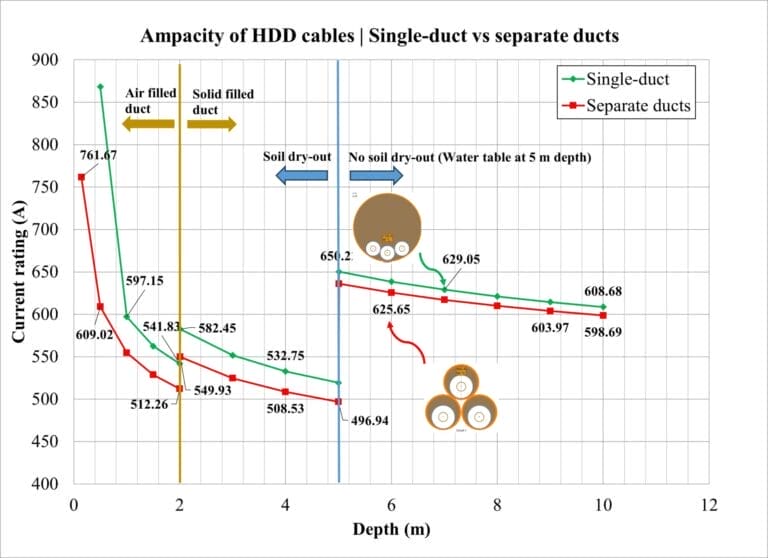

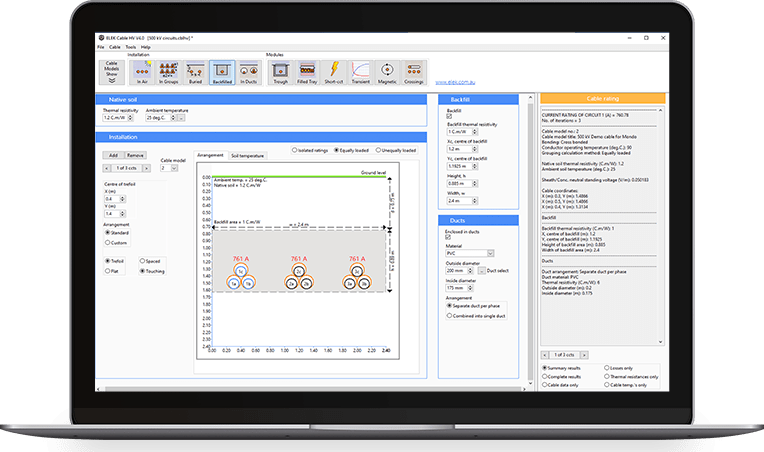

This case study examines the effect of two HDD cable configurations in ducts: Cables in a casing pipe and Cables in separate ducts, as depicted in Figure 5. The article on the ampacity of power cables in ducts provides more details on how ducts impact the ampacity of power cables.

In this study, the size of the duct in a single-duct configuration (Cables in a casing pipe) is considered to be three times that of the smaller ducts in a separate duct configuration, while maintaining the same thickness. The green plot in Figure 5 demonstrates the variation in current rating with depth for cables installed in a single duct, whereas the red plot shows the cables installed in separate ducts. The observations are as follows:

- The Cables in a casing pipe configuration deliver higher ampacity, as the air convection inside the duct benefits from the increasing duct size.

- Ampacity in both configurations is limited by soil dry-out at a depth of approximately 5 m.

Although duct configuration influences performance, soil moisture conditions dominate the thermal behaviour of the HDD installation.

Soil Drying Above the Water Table Level

This case study examines the impact of groundwater levels on the thermal behaviour of HDD cables, as shown in Figure 6. Three scenarios are considered, with water-table depths at 3 m, 5 m, and 7 m, while all other installation conditions remain unchanged. The water table level has a significant effect on the ampacity of cables because the soil below it stays moist and does not dry out. Refer to the free training on soil drying that provides further technical information.

The observations are as follows:

- The cable experiences two potential hot-spot zones: one in the shallow air-filled region and another in the dry-out zone, each creating a local minimum in ampacity.

- A higher water table allows the cable to reach saturated soil sooner, lowering thermal resistivity and increasing ampacity.

- When the water table is deeper, the cable remains in the dry-out zone for a longer stretch, driving the minimum rating downward.

- All cases eventually converge at greater depths, but their minimum ampacities differ notably because each encounters saturation at a different point.

In this study, the groundwater level is one of the strongest determinants of HDD cable rating, outweighing the influence of depth alone.

Strength (Thickness) of PE Ducts

This case study examines the impact of duct strength on the thermal rating of an HDD-installed cable. Duct strength can be represented by the Standard Dimension Ratio (SDR), defined as the pipe’s outside diameter divided by its minimum wall thickness. A higher SDR value means a thinner wall and a less rigid pipe, while a lower SDR value means a thicker wall and a stronger pipe.

Figure 7 illustrates the ampacity of HDD cables for various SDR values. The observations are as follows:

- All three SDR curves overlap almost entirely, indicating that duct wall thickness has a negligible effect on ampacity for the same internal diameter and installation conditions.

- Increasing duct strength improves mechanical robustness but has virtually no impact on the thermal rating of HDD cable installations.

Key Takeaways for HDD Cable Design

- Hot-spots can occur at the deepest air-filled section or just before the water table.

- Air-filled duct and soil dry-out create limiting ampacity sections well above the deepest point.

- Mechanical strength (duct wall thickness) can be added to ducts without compromising ampacity.

- Cables in a casing pipe configuration can provide a 4-5% improvement in rating compared to Cables in separate ducts.

- A higher water table reduces the impact of HDD cable depth on current ratings.

Theory Behind HDD Cable Thermal Behaviour

(2) \(I \propto \frac{1}{ln(d)}\)

Soil Temperature

Soil temperature varies with depth and affects the ampacity of power cables based on their burial depth. It also depends on the time of year and the air temperature. Since HDD cables are installed at different depths, the maximum soil temperature the cable will experience over the year at its installation depth must be taken into consideration.

The maximum soil temperature is higher at shallower depths and is lower at greater depths. For more information on soil temperature calculations for HV cable rating, refer to the article “Soil Temperature Calculations for Power Engineering.”

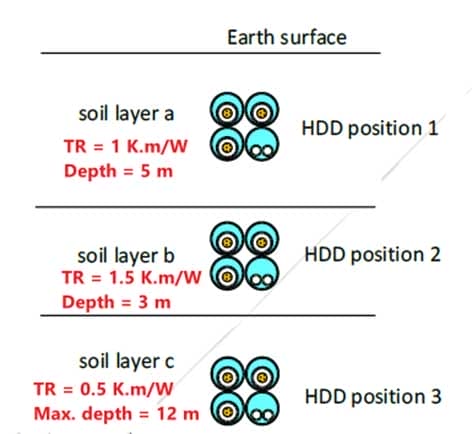

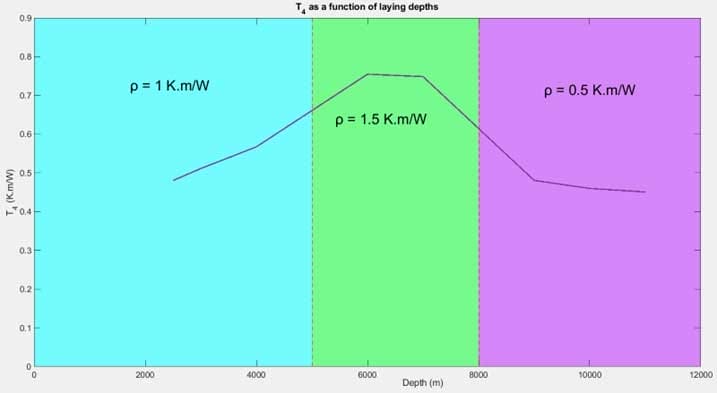

Effect of Soil Layering

HDD routes often cross multiple soil layers with varying thermal resistivities. Each layer affects radial heat flow differently, so the hotspots along the cable route do not necessarily occur at the maximum burial depth or the layer with the highest thermal resistivity. Thermal gradients are dependent on the layer’s thermal resistivity, depth and the angle of the HDD profile.

Figure 8 illustrates the installation conditions of the HDD, where each position corresponds to a different depth of the HDD cables. Figure 9 shows the variation of T4 with depth. Since T4 is proportional to temperature, and hence the current rating, the hotspot will occur in the middle layer with soil TR of 1.5 K.m/W.

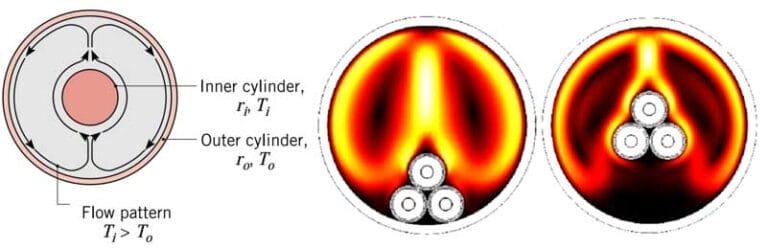

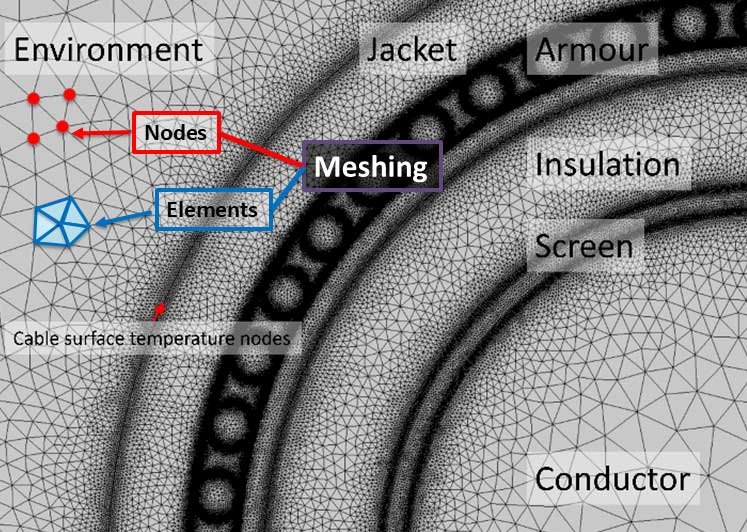

Air Flow and Fill Material

Soil Drying Around HDD Pipes

Key Engineering Takeaways

- Model the HDD cable installation by breaking it down into sections where the cable temperatures are likely to be highest.

- Model the deepest air-filled section of the duct, and the section just above the water table.

- Always consider the effects of the duct filling material and soil dry out in the model.

- Minimise or eliminate air pockets in ducts near entry points to avoid hot spots.

- Include water depth in modelling HDD cables as it significantly affects ampacity.

- Select duct strength based on mechanical requirements, as it has a negligible impact on ampacity.

- Consider a large casing pipe around cables, where practical, for improved current ratings.

References

FAQs for HDD Cable Ampacity

- Does the deepest point of the HDD installation determine cable ampacity?

Yes, but not always. The deepest point of the HDD bore may not be the hottest. The limiting sections can occur in air-filled sections of the ducts and in the dry soil zone above the water table. - Why does ampacity drop sharply in air-filled ducts?

Air has very high thermal resistivity, and convection inside a confined duct is restricted. This leads to poor heat dissipation, resulting in higher cable temperatures and reduced ampacity. - How does soil drying affect HDD cable ratings?

Soil drying occurs when soil temperature rises above a critical dry-out temperature, which is about 40 °C. Moisture migrates outward, increasing thermal resistivity. This significantly reduces heat dissipation and lowers the cable rating. - What role does the water table play in determining the ampacity of HDD cables? Water table depth is one of the strongest determinants of HDD ampacity. A higher water table keeps the soil moist, with lower resistivity, thereby increasing ampacity.

- Does duct wall thickness influence ampacity?

Not much. The study shows SDR 21, 13.6, and 7.4 have almost identical thermal performance. - Are single-duct installations thermally better than multiple ducts?

Yes. Cables in a single duct exhibit roughly 4 to 5 per cent higher ampacity due to improved air convection within a larger conduit. - Is deeper burial always worse for HDD ampacity?

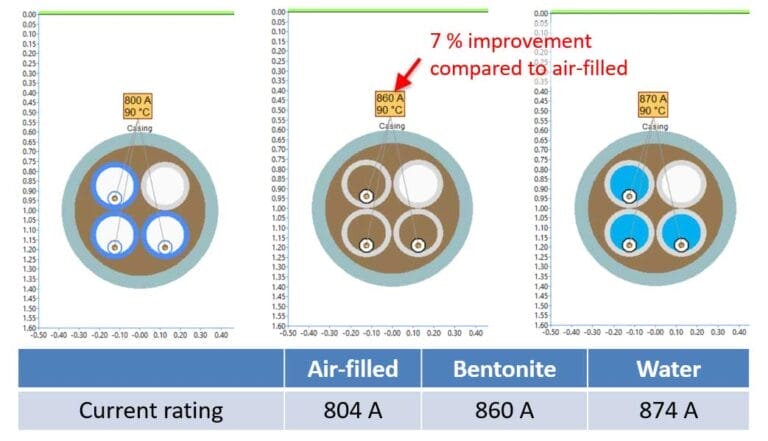

Not always. HDD routes experience varying thermal conditions along their length. Ampacity is often dictated by dry soil or air-filled sections rather than by depth alone. - Which duct fill material provides the best cooling?

Water provides the highest thermal conductivity, followed by bentonite slurry, whereas air-filled ducts perform poorly. - Why is thermal modelling essential for HDD cable installations?

HDD routes include air pockets, grout segments, dry soil, moist soil, and soil layering. These non-uniform conditions make simplified assumptions inaccurate. Proper modelling ensures ratings reflect real thermal behaviour. - What factors should be included in an HDD cable ampacity study?

Key factors include soil dry-out, water table depth, soil resistivity, duct fill material, duct geometry, and route segmentation.