What is a controlled backfill?

It is common practice to place the native soil back into a cable trench on top of the backfill containing the high voltage power cables. However, if the native soil has naturally high thermal resistivity or it will have from being prone to drying out then a controlled backfill with lower resistivity is used. Obviously if the thermal resistivity of the controlled backfill is lower than the native soil then an increase in the current ratings of the cables will occur.

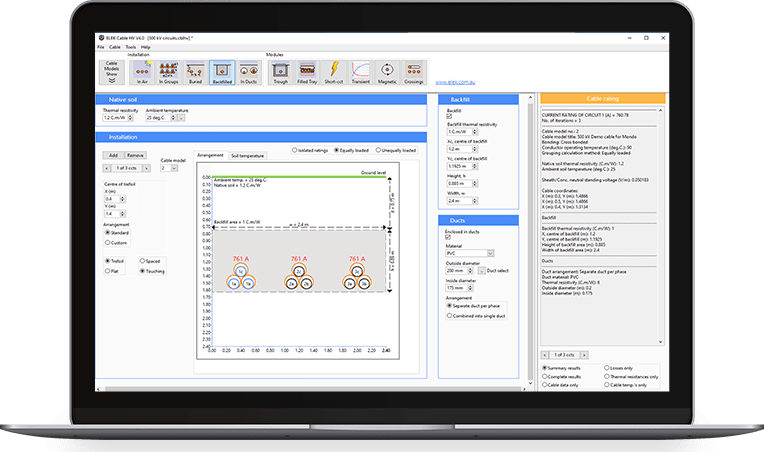

How to model cables in backfill

Figure 1 depicts a cable arrangement with three circuits of single core cables installed inside a thermal backfill with a controlled backfill added on top.

The Standard IEC 60287-1-1 includes the equations for calculating current ratings only for a single backfill surrounding the cables but cannot be used to determine the effects of a controlled backfill on the current rating of the cables. For this situation a numerical algorithm based on the Finite Element Method (FEM) must be used. For further information refer to our article which explains this algorithm.

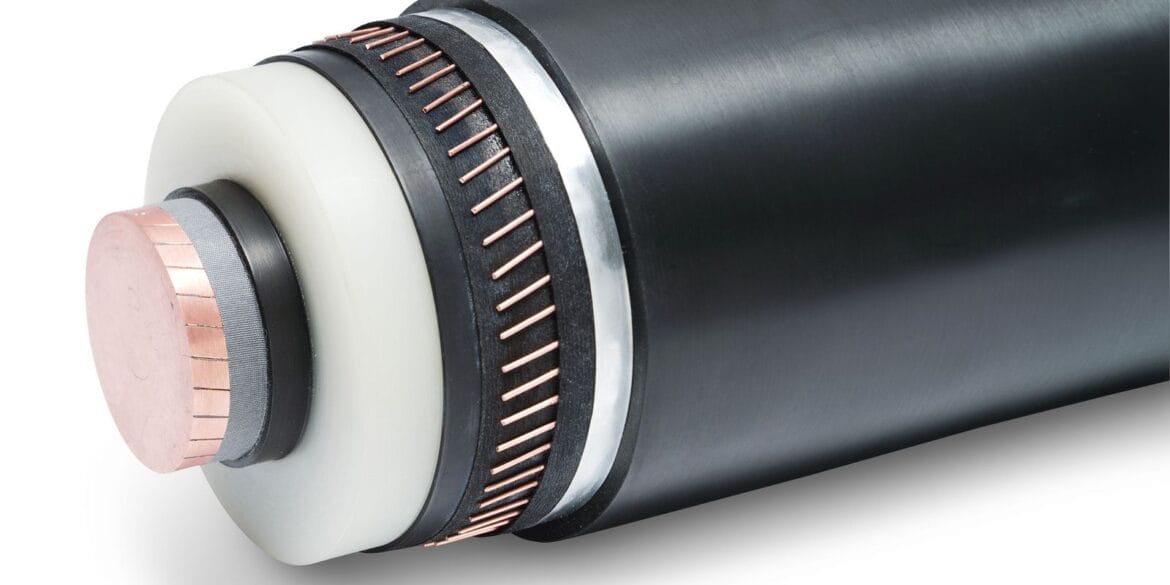

The cable being modelled

Finite element method modelling

Multiple three-phase cable circuits were modelled as installed in a backfill centered at a depth of 1 m with a thermal resistivity of 0.5 K.m/W. The backfill height was 0.5 m and width was 0.7 m. The physical layout of the model along with the FEM meshing is depicted in Figure 3.

All the area inside the model in the image above needs to be meshed; which means subdividing all the components of the model including the cables and separate soil areas into elements. Each element has defined thermal properties and may have many elements which lie inside of it.

Results of the calculations

The study was conducted for the following conditions:

- No controlled backfill

- Controlled backfill thermal resistivity – 0.5 K.m/W

- Controlled backfill thermal resistivity – 1 K.m/W

- Controlled backfill thermal resistivity – 1.5 K.m/W

For each of the controlled backfill thermal resistivities, the native soil thermal resistivity was varied from 0.5 K.m/W to 4 K.m/W. Figure 4 shows current rating of the hottest (centre) circuit, for the various controlled backfill resistivities.

As expected, the results show that when the controlled backfill resistivity decreases, the current rating of the cables conversely will increase. The current rating of the cables improved up to 39.6% when the controlled backfill resistivity was changed from having no effect (same as the native soil of 4 K.m/W) down to 0.5 K.m/W. When the native soil resistivity is 4 K.m/W, the backfill resistivity is 0.5 K.m/W and the controlled backfill resistivity is 1 K.m/W, the improvement in current rating is 21.95%.

In conclusion a controlled backfill which has a better thermal resistivity than the native soil can be used to significantly improved the current rating of buried cables.

References

Leon, F.; Anders, G.J. “Effects of Backfilling on Cable Ampacity Analysed with the Finite Element Method” IEEE Transactions 2008.